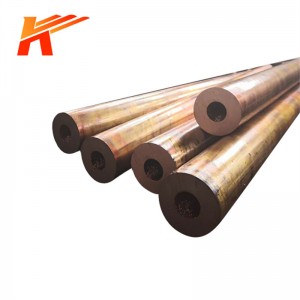

International Standard Chrome Bronze Tube Customization

Introduction

Chromium bronze tube is widely used in high temperature conductive wear parts of electrical equipment. This alloy can be used in the as-cast and deformed states. When Al and Mg are added as alloying elements of chromium bronze, a thin and dense oxide film that is firmly bonded to the base metal can be formed on the surface of the Cu-Cr alloy to improve the high temperature oxidation resistance and heat resistance of the alloy. The content of Mg and Mg in the alloy is usually not more than 0.3%.

Products

Application

Motor commutator, collector ring, high temperature switch, electrode of welding machine, roller, holder, brake disc, disc and other parts requiring high thermal conductivity, electrical conductivity and high heat strength. The use of chrome bronze for these parts, on the one hand, can meet the performance requirements of these parts in use, and on the other hand, because these parts are relatively easy to damage, the products we produce can provide longer product life. On the other hand, because the raw materials are not very expensive, it can be used as an economical choice.

Product Description

| Item | Zirconium Bronze Tube |

| Standard | ASTM, AISI, JIS, ISO, EN, BS, GB, etc. |

| Material | C18150、C18200、C18400、C18500 |

| Size | Diameter: 1-200 - mm

Length: 500-6000mm according to your requirements Size can be customized according to customer needs. |

| Surface | Mill,polished,bright,oiled,hair line,brush,mirror,sand blast,

or as required. |