Because copper has a very good ability to resist corrosion, this is also a very important reason for using copper tubes. It can be used normally in acidic or other corrosive environments. This is also a very important reason why it can be used for corrosion resistance in so many industries. In addition, there is another very good function. Copper has very good delicate welding ability and is relatively easy to shape, which can play a great role in industrial production.

First of all, copper tubes not only have the characteristics of ordinary copper tubes, but also have very good usability. Using them can well prevent various mechanical equipment from being corroded. Moreover, the ingredients inside are very common, so the price is not very high, within the acceptable range. In this way, more people use it, and it can be used to complete the anti-corrosion work very well.

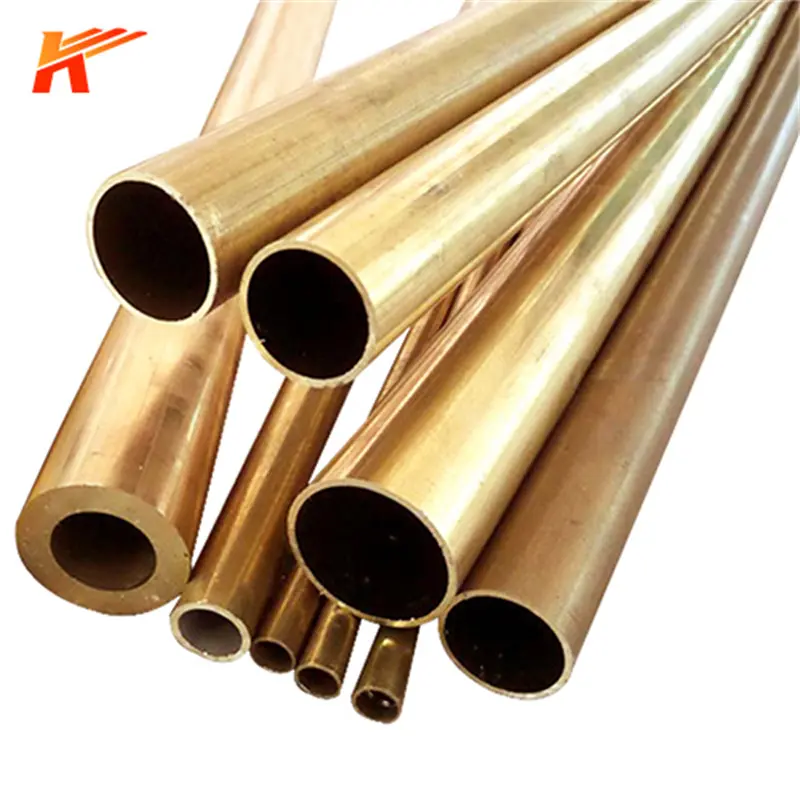

The copper tube is light in weight, has good thermal conductivity and high strength at low temperature. It is often used to manufacture heat exchange equipment (such as condensers, etc.), and is also used to assemble low-temperature pipelines in oxygen production equipment. Copper tubes with small diameters are often used to transport pressurized liquids (such as lubrication systems, oil pressure systems, etc.) and pressure measuring tubes used as instruments.

Compared with copper pipes, the disadvantages of many other pipe materials are obvious. For example, galvanized steel pipes used in residential buildings in the past are very easy to rust, and the tap water will turn purple and the water flow will become smaller after a short period of use. There are also some materials whose strength will decrease rapidly at high temperatures, which will cause unsafe hazards when used in hot water pipes. However, since the melting point of copper is as high as 1083 degrees, its influence by the temperature of the hot water system is basically negligible.

Post time: Nov-23-2022