-

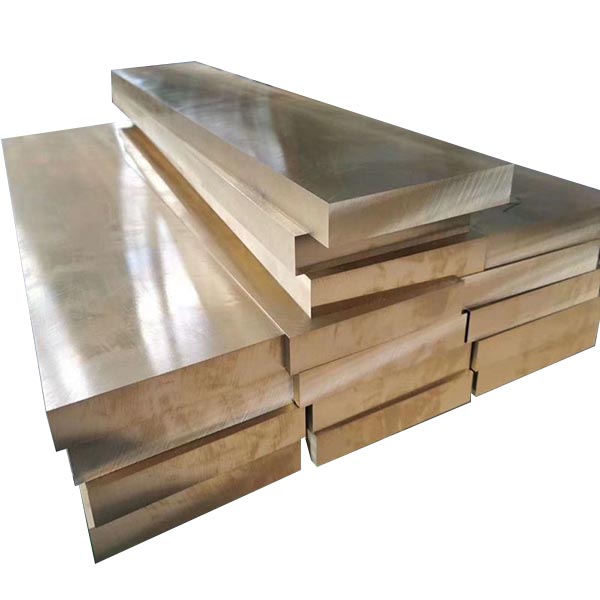

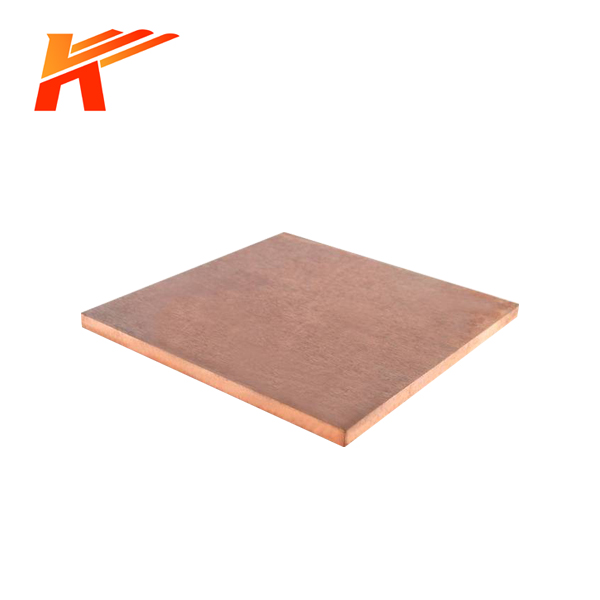

How to prevent defects from tin bronze plate

The defects of the tin bronze plate are mainly manifested in the unreasonable structural design of the casting, sharp corners, and the wall thickness of the casting is too different; the sand mold (core) has poor retreat; the mold is partially overheated; the pouring temperature is too high; Prem...Read more -

Welding between tin bronze plate and steel

Tin bronze plate is very resistant to corrosion in the atmosphere, sea water, fresh water and steam, and is widely used in steam boilers and marine ship parts. The solidification range of the tin bronze plate is large, and the dendrite segregation is serious; it is not easy to form concentrated s...Read more -

Performance Advantages of Cast Copper Alloys

Copper alloy is an alloy composed of pure copper as the matrix and one or several other elements added. According to the material formation method, it can be divided into cast copper alloy and deformed copper alloy. Most cast copper alloys cannot be press worked, such as cast beryllium bronze and...Read more -

Extensive use of aluminum bronze in life

Aluminum bronze won’t produce sparks under impact, and may be wont to make non-sparking tool materials. it’s excellent thermal conductivity and stable stiffness. it’s the benefits of scratching the workpiece so on, and has become a replacement sort of mold material. it’s p...Read more -

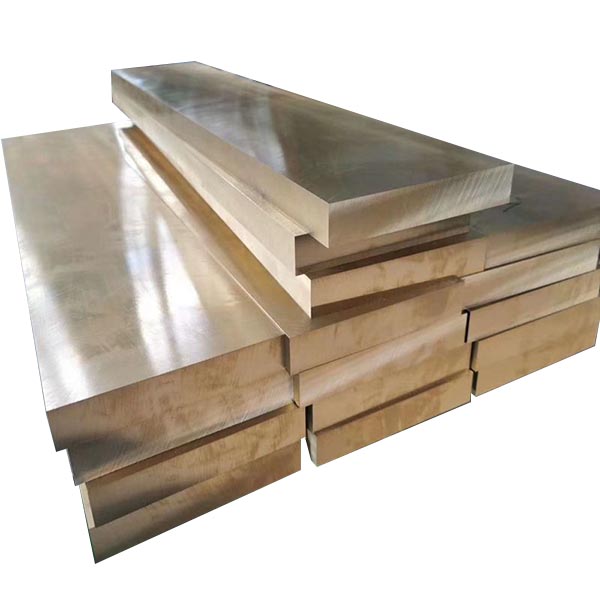

The casting process of tin bronze plate

Tin bronze plate casting is bronze wont to produce castings. Bronze castings are widely employed in machinery manufacturing, ships, automobiles, construction and other industrial sectors, forming cast bronze series in heavy non-ferrous metal materials. Commonly used cast bronzes are tin bronze pl...Read more -

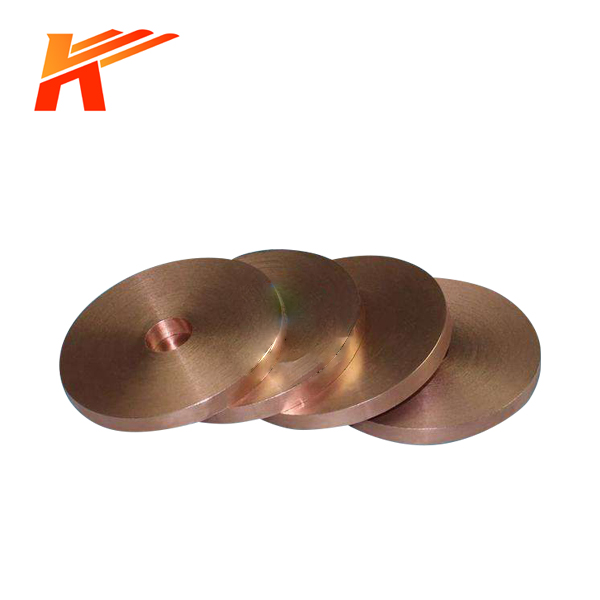

Application scope of tungsten copper plate

Tungsten copper plate combines the advantages of metal tungsten and copper. Among them, tungsten has a high melting point and high density. The melting point of tungsten is 3410 degrees Celsius, and the melting point of copper is 1083 degrees Celsius. Copper has excellent electrical and thermal c...Read more -

Precautions for processing tungsten copper sheet

Tungsten-copper sheet, a metal material, is a two-phase structure pseudo-alloy mainly composed of tungsten and copper elements. It is a metal matrix composite material. Due to the great difference in physical properties between metal tungsten and tungsten, it cannot be produced by the melting and...Read more -

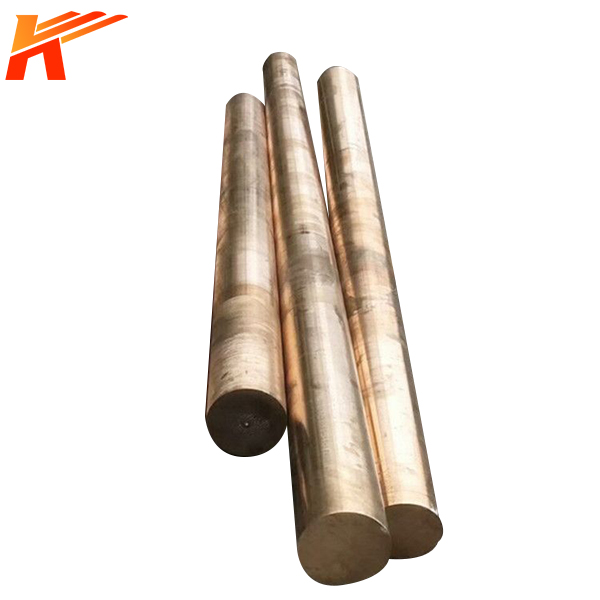

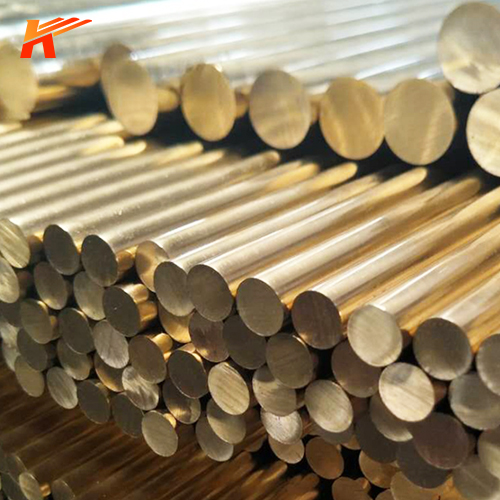

Principle of copper rod forming process

1. All elements reduce the electrical conductivity and thermal conductivity of the copper rod without exception. All elements are dissolved in the copper rod, causing the lattice distortion of the copper rod, causing wave scattering when the free electrons flow directionally, making the resistivi...Read more -

Copper rod forming process and process

Before introducing the copper rod forming process and process, what are the metal forming processes? 1. Metal solidification and forming is customarily called casting. Casting is a process in which molten metal is poured, injected or inhaled into a mold cavity, and after it solidifies, a casting ...Read more -

Precautions in the extrusion process of brass rods

During the extrusion process of the brass rod, the ingot is subjected to three-way compressive stress in the extrusion cylinder and can withstand a large amount of deformation; when extruding, it should be based on the characteristics of the alloy, the specifications and technical requirements of...Read more -

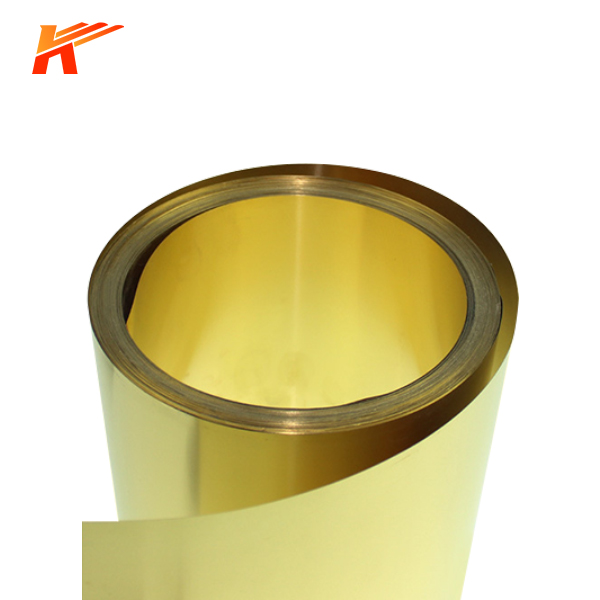

Common Classification of Copper Alloys

Classification of Copper Alloys: By Alloy System 1. Unalloyed copper: Unalloyed copper includes high-purity copper, tough copper, deoxidized copper, oxygen-free copper, etc. In general, pure copper is also called red copper. 2. Other copper alloys belong to alloy copper. In my country and Russia,...Read more -

Characteristics and Application of Chromium Zirconium Copper

Chromium zirconium copper (CuCrZr) chemical composition (mass fraction) % (Cr: 0.1-0.8, Zr: 0.3-0.6) hardness (HRB78-83) conductivity 43ms/m softening temperature 550 ℃ Chromium zirconium copper features high strength And hardness, electrical conductivity and thermal conductivity, wear resistance...Read more