-

Reverse extrusion technology and selection principle of brass sheet

With the development of economy and science and technology, the quality requirements of extruded products are higher and higher, and some special requirements are put forward in some aspects, which promote the rapid development of brass sheet reverse extrusion technology. A new type of reverse ex...Read more -

Copper strip control surface quality measures

Copper strip high purity, fine tissue, oxygen content is very low. It has good electrical conductivity, thermal conductivity, corrosion resistance and machining properties, and can be welded and brazed. Measures to control the surface quality of red copper strip: first of all, we should strengthe...Read more -

Brass strip application and processing

Brass strip is a long conductor of rectangular or chamfered sections made of copper, used to carry current in circuits and connect electrical equipment. Because copper is better than aluminum in conducting electricity, brass strip has been widely used in electrical equipment, especially in power ...Read more -

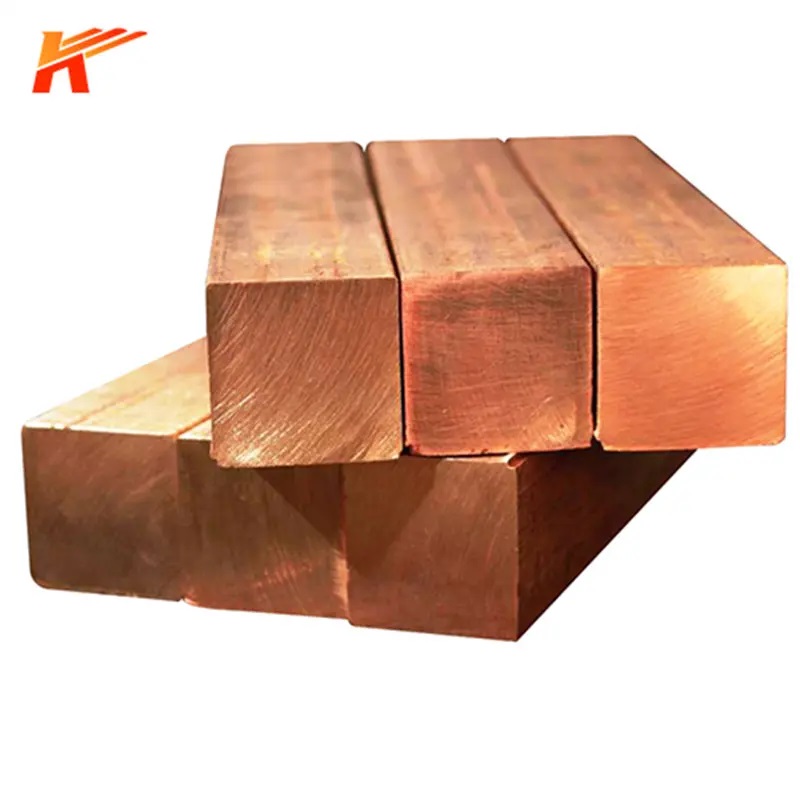

Control method of surface quality of copper busbar

Surface quality control is the whole process of copper busbar production to product packaging control, is a fine management, careful operation of the system engineering, each process is the key to control product surface quality. The quality of billet surface is greatly affected by whether the co...Read more -

Brass sheet grinding process

Brass sheet polishing refers to the selection of a reflection of the effect, so that the surface of brass sheet is not smooth level shrink, make it more and more bright, leveling the surface of the solution. The key to polishing brass is to adopt two methods: mechanical chemical method and physic...Read more -

Influencing factors of copper busbar surface quality

Copper busbar products are mainly used in power, electronics, communication, heat dissipation, mold and other industries. With the development of national economy and the increasingly fierce market competition, users have higher and higher requirements on the surface quality of copper bus product...Read more -

Technology of silicon bronze

The casting process of silicon bronze: melting and pouring. Silicon bronze is smelted in an acid induction furnace. The charge should be preheated to 150~200℃ before being put into the furnace, and the electrolytic copper should be cleaned up, roasted at high temperature and thoroughly deoiled be...Read more -

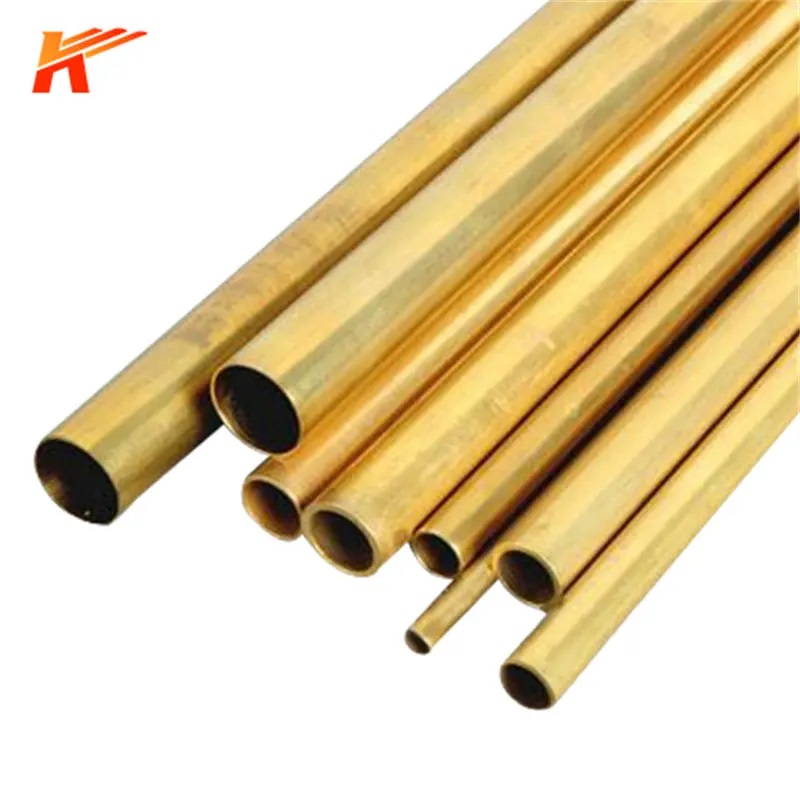

Seamless brass tube with good performance characteristics

Seamless brass tube this product in today’s daily life application is more common, many places will use this product. But even with such a common product, there are still many people who are not particularly familiar with its performance characteristics. Then, the following is a brief intro...Read more -

Preparation method and application of high purity copper

High purity copper refers to the purity of copper reaches 99.999% or higher 99.9999%, and its various physical properties are greatly improved than those with low purity. Copper has good electrical and thermal conductivity, and it is malleable and malleable. Copper is commonly used to make wires ...Read more -

The technology of tungsten copper electroplating was analyzed

Tungsten copper alloy not only has the low expansion characteristic of tungsten, but also has the high thermal conductivity characteristic of copper. By changing the proportion of tungsten and copper, the thermal expansion coefficient and thermal conductivity function of tungsten and copper alloy...Read more -

Thick-walled aluminum bronze production process

Using physical principles, the purity of thick-walled aluminum bronze can be measured, the volume and mass of the sample can be measured, and the proportion of copper in bronze can be calculated based on the density of copper and zinc. A multi-component alloy made by adding other alloying element...Read more -

Solutions to common problems with copper tape

1. The solution to the discoloration of copper tape (1) Control the concentration of acid solution during pickling. In the case of washing off the oxide layer on the surface of the annealed copper strip, a high acid concentration does not make any sense. On the contrary, if the concentration is t...Read more