-

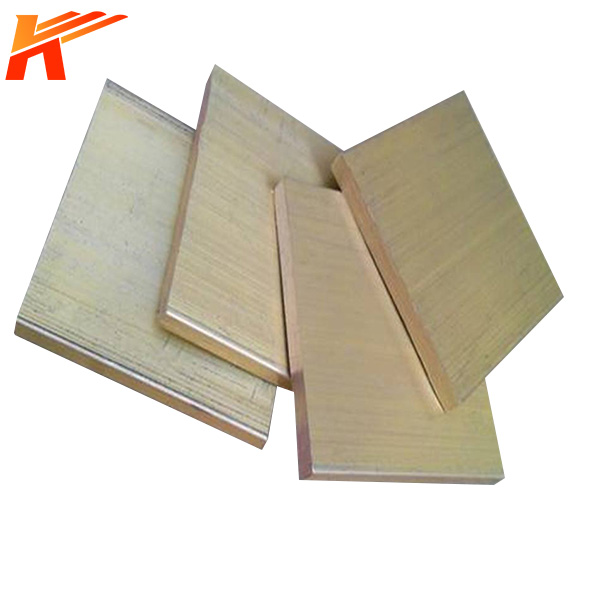

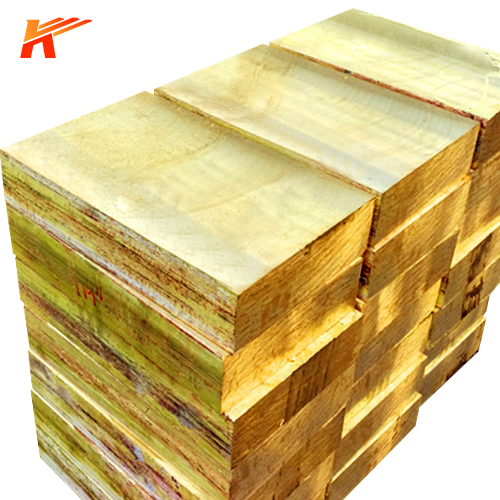

Uses and Quality Control of Brass Rods

Brass rods are rod-shaped objects made of copper and zinc alloys, named for their yellow color. Brass with a copper content of 56% to 68% has a melting point of 934 to 967 degrees. Brass has good mechanical properties and wear resistance, and can be used to manufacture precision instruments, ship...Read more -

Some knowledge about bearings

Aluminum bronze can be used to produce bearing related products. [Standard bearing]: The inner diameter or outer diameter, width (height) and size of the standard bearing conform to the bearing shape specified in GB/T 273.1-2003, GB/T 273.2-1998, GB/T 273.3-1999 or other relevant standards size. ...Read more -

Effects of Oxidative Coloring of Brass Rods

Brass rods are easily oxidized when exposed to the air for a long time, so is there any good measure to prevent the oxidation of brass rods? 1 Pair of brass rods are sealed and packaged, and two bags of desiccant are added at the same time. 2 The wooden shaft and the wooden box board are dried. 3...Read more -

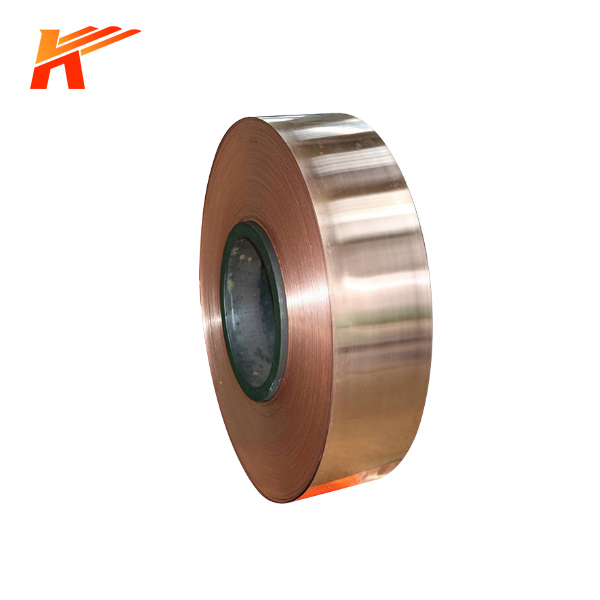

Expert knowledge on storage methods of copper rods

Expert knowledge on storage methods of copper rods 1. We have to set up the warehouse. The temperature of placing the copper is 15 to 35 degrees in the middle. The oxygen-free copper rod and metal wire drawing copper plate must bypass the water source. What is the storage method of the copper rod...Read more -

Oxidation reasons and treatment methods of copper rods

The important factor affecting the surface quality of purple copper rods is the production process, and is closely related to all production processes. The reasons for the oxidation of red copper rods are as follows: 1. The pre-drying time of the insert is too long. 2. The acid corrodes the coppe...Read more -

What are the main varieties of white copper plate?

In our daily life, we will use a lot of metal products. Many metal products are synthetic. The white copper sheet is a copper alloy with nickel as the main alloy and no element. Based on copper-nickel alloys, cupronickel rods with third elements such as zinc, manganese, aluminum, etc. are added, ...Read more -

What is the main purpose of white copper? How can it be distinguished from silver?

We use a lot of metals in our lives, and there are metals in various products. White copper is a copper-based alloy with nickel as the main added element. It is silver-white and has metallic luster, so it is named cupronickel. Copper and nickel can be infinitely dissolved in each other, thus form...Read more -

How to Melt Aluminum Brass

The aluminum brass series is more complicated, and some of the complex aluminum brass contain the third and fourth alloying elements such as manganese, nickel, silicon, cobalt and arsenic. HAl66-6-3-2 and HAl61-4-3-1, which have more alloying elements, are alloys composed of six elements, and som...Read more -

How to Smelt Simple Brass

Raw material selection The raw material taste should improve with the taste of brass varieties. When smelting non-essential brass, if the quality of the charge is reliable, sometimes the use of old material can reach 100%. However, in order to ensure the quality of the melt and reduce the burning...Read more -

Changes in properties of chromium zirconium copper after heat treatment

After solution aging treatment, fine black precipitates are densely distributed at the grain boundaries of chromium zirconium copper, and many small black precipitates are also distributed in the grain, with a size of about a few microns. As the temperature decreases, the curve approaches the cop...Read more -

What is the difference in performance between tin bronze and beryllium bronze?

Tin bronze is actually a metal material with tin as the main alloying element, and its tin content is generally between 3-14%. This material is mainly used to make elastic components and wear-resistant parts, deformed tin bronze The content of tin does not exceed 8%, and sometimes lead, phosphoru...Read more -

Hardness of brass

Ordinary Brass It is an alloy of copper and zinc. When the zinc content is less than 39%, zinc can dissolve in copper to form single-phase a, called single-phase brass, which has good plasticity and is suitable for hot and cold press processing. When the zinc content is more than 39%, there is a ...Read more