-

Heat Treatment Process of Tin Bronze Contacts

Some switchgear contact parts are made of tin bronze material, which requires good elasticity, wear resistance, anti-magnetic and corrosion resistance. Due to the complex shape of the part, in the process of stamping and bending, in order to make the workpiece have sufficient toughness while main...Read more -

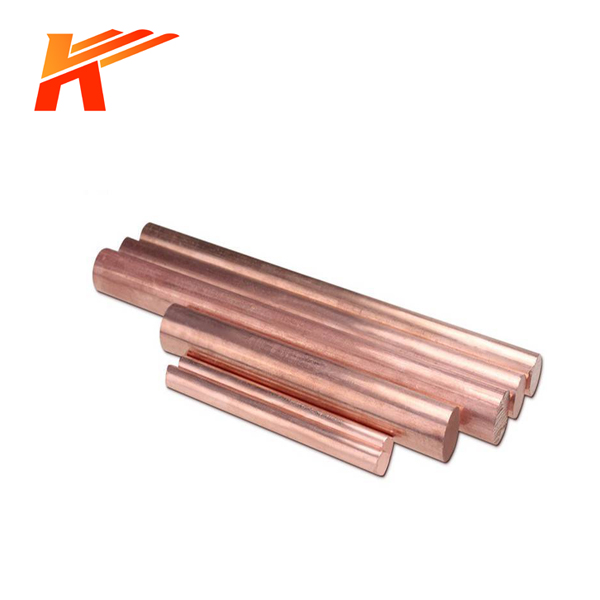

The use of copper in production and life

conductivity of copper One of the most important properties of lead-free copper is that it has excellent electrical conductivity, with a conductivity of 58m/(Ω.mm square). This property makes copper widely used in the electronics, electrical, telecommunications and electronics industries. This hi...Read more -

Copper alloy corrosion

Copper alloys have excellent resistance to atmospheric and seawater corrosion, such as silicon bronze, aluminum bronze and so on. In general media, it is dominated by uniform corrosion. There is strong stress corrosion susceptibility in the solution in the presence of ammonia, and there are also ...Read more -

Application of Copper in Light Industry

Application of Copper in Paper Industry In the current information-changing society, paper consumption is huge. The paper looks simple on the surface, but the papermaking process is very complex, requiring many steps and the application of many machines, including coolers, evaporators, beaters, p...Read more -

What are the factors that cause copper alloy corrosion

Copper alloy corrosion atmospheric corrosion The atmospheric corrosion of metal materials mainly depends on the water vapor in the atmosphere and the water film on the surface of the material. The relative humidity of the atmosphere when the corrosion rate of the metal atmosphere begins to increa...Read more -

Applications and uses of lead-free copper

Applications and uses of lead-free copper 1. It is suitable for all kinds of cold heading, bending and riveting parts, electronic and telecommunication connectors, connectors and other parts with ecological environmental protection and health and safety requirements. 2. It is suitable for automat...Read more -

Smelting properties of tin bronze

The most harmful impurities in tin bronze are aluminum, silicon and magnesium. When their content exceeds 0.005%, the resulting SiO2, MgO and Al2O3 oxide inclusions will contaminate the melt and reduce the performance of some aspects of the alloy. When smelting tin bronze, since the boiling point...Read more -

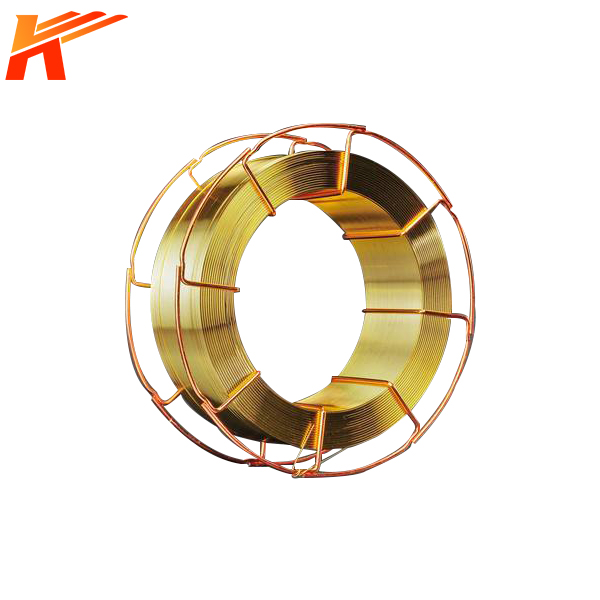

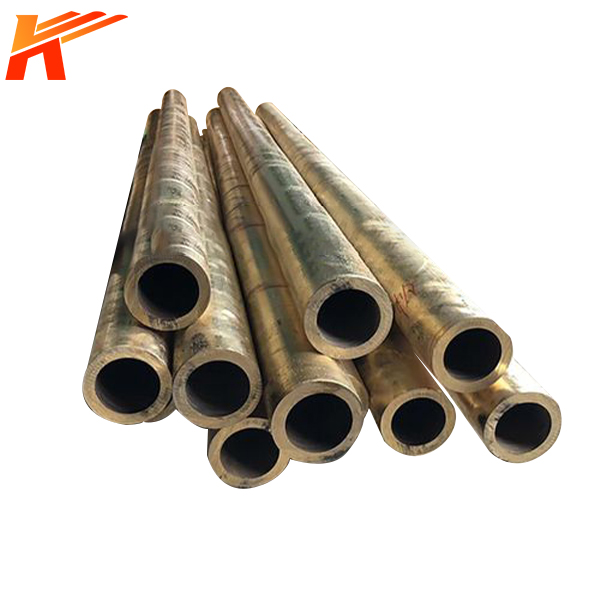

Different grades of tin bronze

Tin bronze has been widely used in various industrial sectors for a long time. However, the grades of tin bronze are different, and their performance and uses are also different. QSn4-3: It has good elasticity, wear resistance and diamagnetism, and has good processing performance in hot and cold ...Read more -

Copper alloy composition detection and characteristics

Copper alloy composition detection and characteristics? What are the detection methods of copper alloy composition? Copper alloy composition detection steps? What are the characteristics of copper alloy composition detection? The copper alloy composition we are talking about here mainly refers to...Read more -

How to identify the type of copper alloy

How to identify the type of copper alloy? White copper, brass, red copper (also known as “red copper”), and bronze (blue-gray or gray-yellow) are distinguished by color. Among them, white copper and brass are very easy to distinguish; red copper is pure copper (impurities <1%) and ...Read more -

The production process of tungsten copper alloy

The production process of tungsten copper alloy: The technical process of preparing tungsten-copper alloy by powder metallurgy method is used for mixing, limiting, forming, sintering, melting, infiltration and cold production of powdered ingredients. Tungsten-copper or molybdenum-copper mixed pow...Read more -

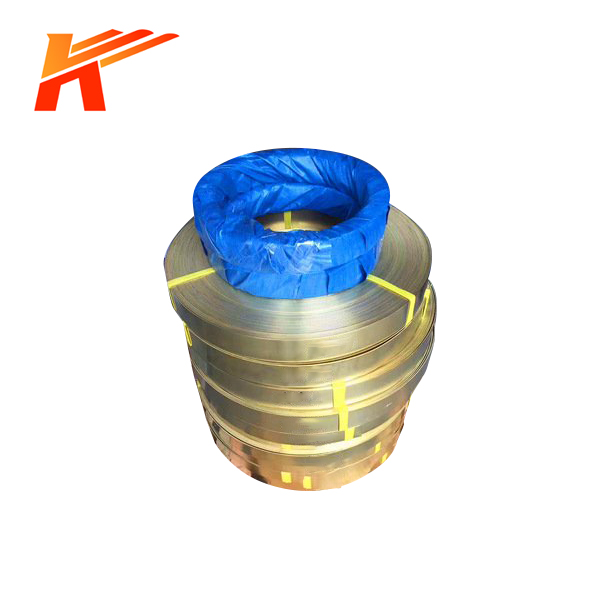

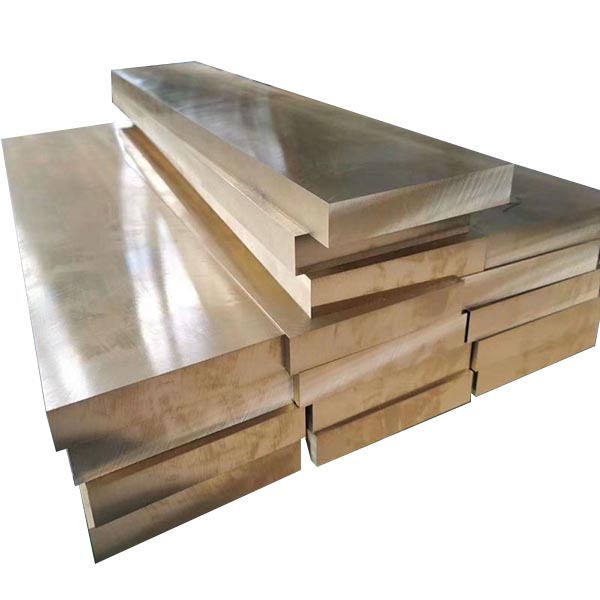

Can aluminum bronze be replaced by tin bronze plate

Can aluminum bronze be replaced by tin bronze plate? As an elastic alloy, tin bronze plate refers to a copper-tin alloy containing Sn≤6.5%, usually still containing P, Zn and other alloy elements. If it also contains P, it is called phosphor-tin bronze, which has high elastic limit, elastic modul...Read more