-

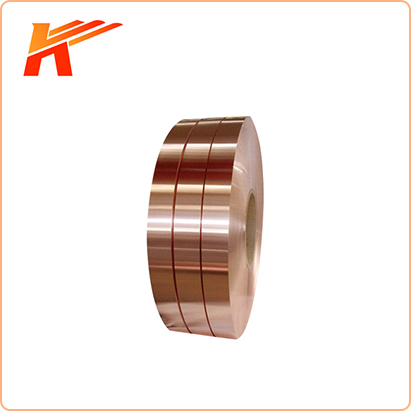

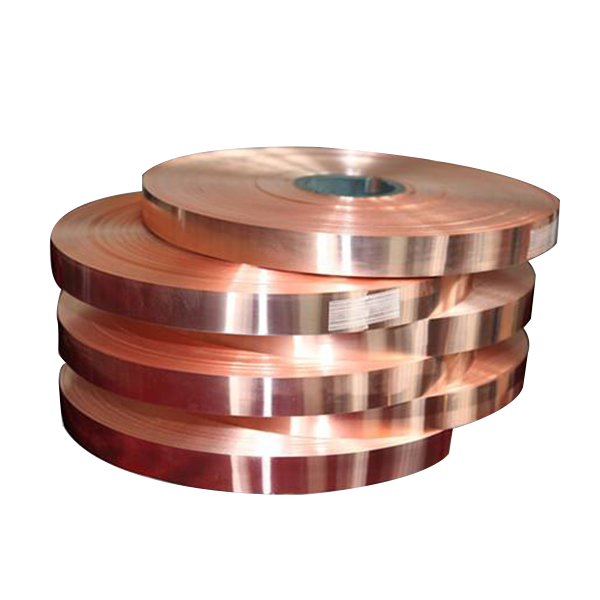

Processing method of copper and copper alloy sheet, strip and foil

Processing method of copper and copper alloy sheet, strip and foil: Rolling is the basic method for the production of copper and copper alloy strips. Rolling is in a gap between two rolls that have a certain pressure on each other and rotate in opposite directions to roll out the product, and the...Read more -

What are the casting methods for lead-free copper sleeves?

Sand casting is the most common method for copper gaskets used in sand casting production, which has the advantages of wide adaptability and relatively simple production preparation. However, the dimensional accuracy, surface quality, and internal quality of castings produced by this method are f...Read more -

Application of various grades of tin bronze

QSn4-3 tin bronze: tin bronze containing zinc. It has high wear resistance and elasticity, good anti-magnetic properties, can withstand hot or cold pressure processing well; in hard state, good machinability, easy welding and brazing, corrosion resistance in atmosphere, fresh water and sea water ...Read more -

Welding properties of various copper alloys

Welding properties of various copper alloys: 1. The thermal conductivity of red copper is high. The thermal conductivity of red copper at room temperature is about 8 times larger than that of carbon steel. It is difficult to locally heat the copper weldment to the melting temperature. Therefore, ...Read more -

Use of special brass

In order to meet the requirements of making structural parts, it is widely used in the industry to add alloying elements to copper to make copper alloys with enhanced properties. Brass is a copper alloy with zinc as the main alloying element, which has good mechanical properties and is easy to pr...Read more -

Performance Advantages of Cast Copper Alloys

1. Process characteristics: Most copper alloys have large shrinkage, that the solidification sequence should be controlled during casting to stop the formation of shrinkage cavities. Tin bronze is well oxidized within the liquid state, that the flow shouldn’t be interrupted during pouring. ...Read more -

What are the ways to identify pure copper

1. Check the hardness: the higher the fineness of copper jewelry, the softer the texture and the whiter and smoother the surface. Copper alloy manufacturers take copper bracelets of about 60 grams as an example. If they are pulled open by hand, there is no elasticity, and their fineness is about ...Read more -

Application of beryllium copper alloy in automobile mould

The conclusion of the application of beryllium copper alloy in automobile die The stamping operation of automobile panel is one of the four major processes of vehicle manufacturing, and it is the primary link in body manufacturing. The quality level of stamping parts lays the foundation for the q...Read more -

Why do many plastic mold manufacturers choose beryllium copper?

Nowadays, more and more plastic mold manufacturers have begun to use beryllium copper mold materials. Among many metal materials, what makes beryllium copper more and more popular? What kind of characteristics make it stand out? Maybe many people don’t know what kind of metal beryllium copp...Read more -

What are the material selection methods for brass copper alloys?

Brass has good processing performance and is often used for cutting into various accessories. Among them, the most used brass material in cutting is Pb-containing brass. Lead-containing brass has excellent chemical, physical, mechanical and free cutting properties, and is the most widely used cop...Read more -

Chemical Properties of Lead-Free Copper

Lead-free copper has a high positive potential, cannot replace hydrogen in water, and has excellent corrosion resistance in the atmosphere, pure water, seawater, non-oxidizing acid, alkali, salt solution, organic acid medium and soil, but copper is easily oxidized , when the temperature is greate...Read more -

Selection of Annealing Process for Tin Bronze Sheet

1. Heating temperature, holding time and cooling method: The phase transition temperature of the tin bronze plate from α→α+ε is about 320 ℃, that is, the heating temperature is higher than 320 ℃, and its structure is a single-phase structure, until it is heated to 930 The liquid phase structure a...Read more