Brass strips has extremely good plasticity and high strength, good machinability, easy welding, and is very stable against general corrosion. Brass strip is an alloy of copper and zinc, named for its yellow color. In fact, there are many types of brass strips in the market, such as H96, H90, H85, H70, H68, etc. In this article, the editor will take you to understand the introduction of these types and related uses:

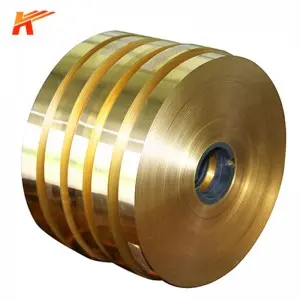

brass strip

1. The performance of H90 brass strip is similar to that of H96, but its strength is slightly higher than that of H96. It can be plated with metal and coated with enamel.

Uses: Water and drain pipes, medals, artwork, tank straps, and bimetallic strips.

2. H85 brass strip has high strength, good plasticity, can withstand heat and pressure processing well, and has good welding and corrosion resistance.

Uses: Condensation and heat dissipation pipes, siphon pipes, serpentine pipes, and cooling equipment.

3. H96 brass strip has higher strength than pure copper, good thermal conductivity and electrical conductivity, high corrosion resistance in the atmosphere and fresh water, and good plasticity, easy to cold and hot pressure processing, easy to weld, forge and tin-plated, no stress Prone to corrosion cracking.

Uses: Used as conduits, condensation pipes, radiator pipes, heat sinks, automobile water tank belts and conductive parts in general machinery manufacturing.

4. H70 and H68 brass have good plasticity and high strength, good machinability, easy welding, very stable to general corrosion, but prone to corrosion and cracking. H68 is widely used in ordinary brass. One variety, H68A, is added with a small amount of arsenic (As), which can prevent brass from dezincification and improve the corrosion resistance of brass.

Uses: Complex cold stamping and deep stamping parts, such as radiator shells, conduits, bellows, cartridge cases, gaskets, etc.

Post time: Jan-10-2023