Company News

-

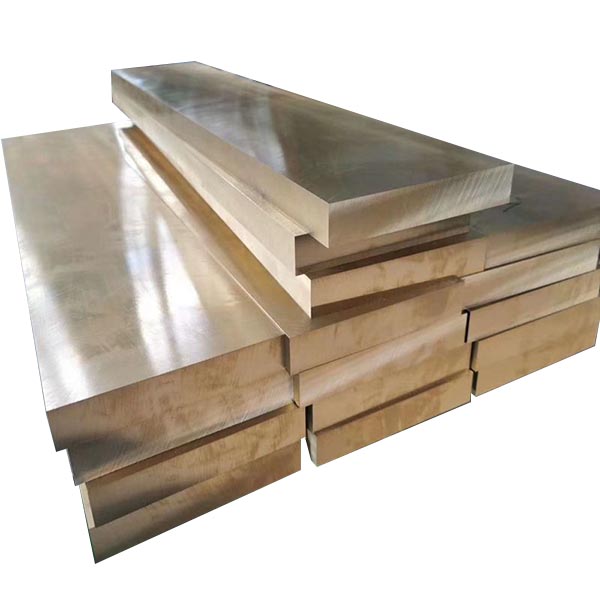

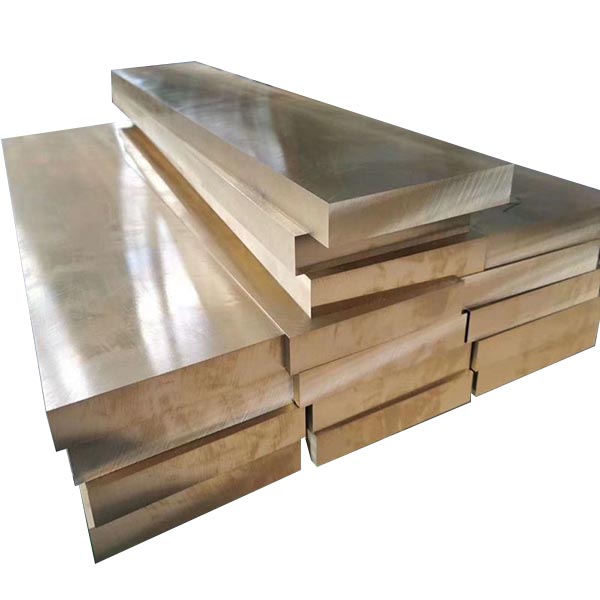

Processing method of copper and copper alloy sheet, strip and foil

Processing method of copper and copper alloy sheet, strip and foil: Rolling is the basic method for the production of copper and copper alloy strips. Rolling is in a gap between two rolls that have a certain pressure on each other and rotate in opposite directions to roll out the product, and the...Read more -

Application of various grades of tin bronze

QSn4-3 tin bronze: tin bronze containing zinc. It has high wear resistance and elasticity, good anti-magnetic properties, can withstand hot or cold pressure processing well; in hard state, good machinability, easy welding and brazing, corrosion resistance in atmosphere, fresh water and sea water ...Read more -

Use of special brass

In order to meet the requirements of making structural parts, it is widely used in the industry to add alloying elements to copper to make copper alloys with enhanced properties. Brass is a copper alloy with zinc as the main alloying element, which has good mechanical properties and is easy to pr...Read more -

What are the ways to identify pure copper

1. Check the hardness: the higher the fineness of copper jewelry, the softer the texture and the whiter and smoother the surface. Copper alloy manufacturers take copper bracelets of about 60 grams as an example. If they are pulled open by hand, there is no elasticity, and their fineness is about ...Read more -

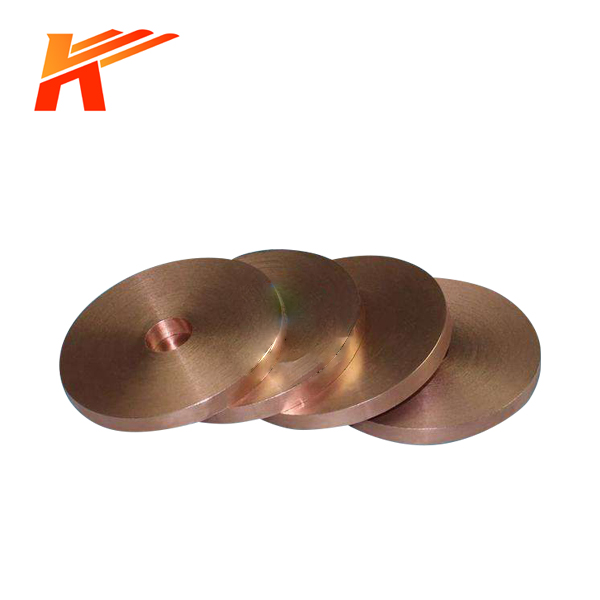

Why do many plastic mold manufacturers choose beryllium copper?

Nowadays, more and more plastic mold manufacturers have begun to use beryllium copper mold materials. Among many metal materials, what makes beryllium copper more and more popular? What kind of characteristics make it stand out? Maybe many people don’t know what kind of metal beryllium copp...Read more -

Chemical Properties of Lead-Free Copper

Lead-free copper has a high positive potential, cannot replace hydrogen in water, and has excellent corrosion resistance in the atmosphere, pure water, seawater, non-oxidizing acid, alkali, salt solution, organic acid medium and soil, but copper is easily oxidized , when the temperature is greate...Read more -

How to prevent defects from tin bronze plate

The defects of the tin bronze plate are mainly manifested in the unreasonable structural design of the casting, sharp corners, and the wall thickness of the casting is too different; the sand mold (core) has poor retreat; the mold is partially overheated; the pouring temperature is too high; Prem...Read more -

Performance Advantages of Cast Copper Alloys

Copper alloy is an alloy composed of pure copper as the matrix and one or several other elements added. According to the material formation method, it can be divided into cast copper alloy and deformed copper alloy. Most cast copper alloys cannot be press worked, such as cast beryllium bronze and...Read more -

The casting process of tin bronze plate

Tin bronze plate casting is bronze wont to produce castings. Bronze castings are widely employed in machinery manufacturing, ships, automobiles, construction and other industrial sectors, forming cast bronze series in heavy non-ferrous metal materials. Commonly used cast bronzes are tin bronze pl...Read more -

Precautions for processing tungsten copper sheet

Tungsten-copper sheet, a metal material, is a two-phase structure pseudo-alloy mainly composed of tungsten and copper elements. It is a metal matrix composite material. Due to the great difference in physical properties between metal tungsten and tungsten, it cannot be produced by the melting and...Read more -

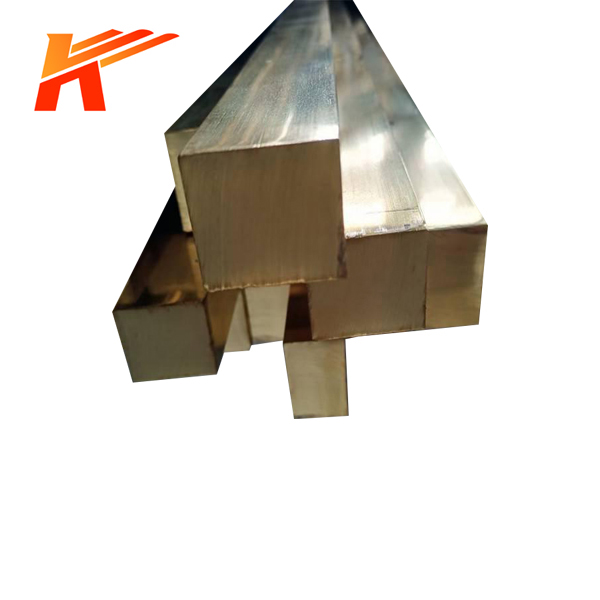

Copper rod forming process and process

Before introducing the copper rod forming process and process, what are the metal forming processes? 1. Metal solidification and forming is customarily called casting. Casting is a process in which molten metal is poured, injected or inhaled into a mold cavity, and after it solidifies, a casting ...Read more -

Common Classification of Copper Alloys

Classification of Copper Alloys: By Alloy System 1. Unalloyed copper: Unalloyed copper includes high-purity copper, tough copper, deoxidized copper, oxygen-free copper, etc. In general, pure copper is also called red copper. 2. Other copper alloys belong to alloy copper. In my country and Russia,...Read more