Industry News

-

Brass Tube Features

Brass tubes are very common in daily life and are used in many fields. For example, the general cable protection and faucet hardware industries are using large amounts of brass tubing. This kind of pipe has good wear resistance and lubrication effect and can play a good role in many industries. F...Read more -

Treatment of chromium-zirconium copper after oxidation

Chromium-zirconium copper is mainly used for welding in the machinery manufacturing industry, where mechanical and physical properties can be obtained. When this material is used as a general resistance welding, the treatment methods of this material after oxidation are as follows. The vinegar so...Read more -

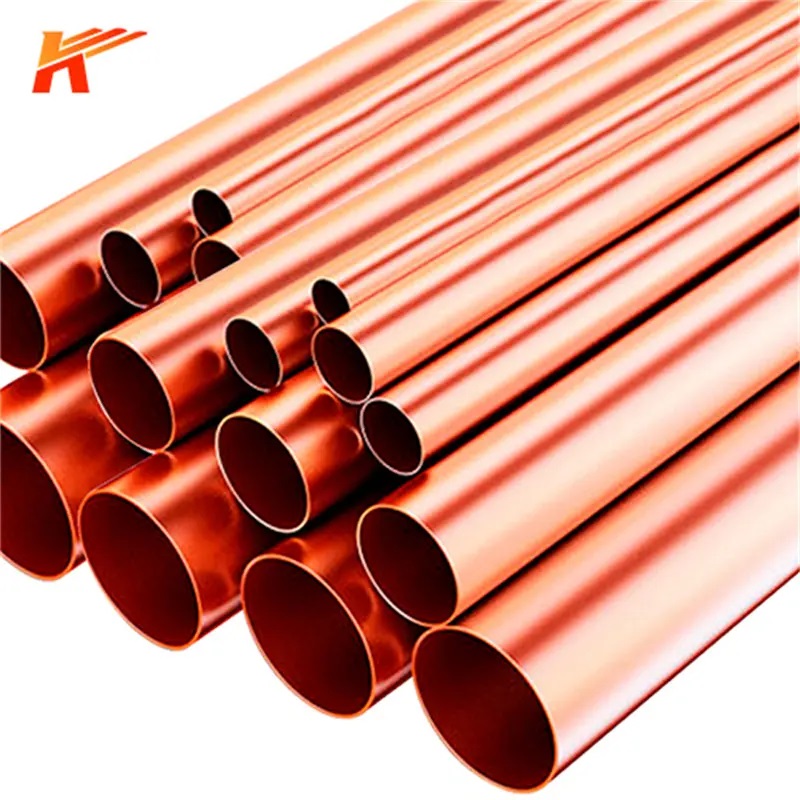

The advantage of copper tube

1. Safe and reliable: copper tube integrates the advantages of metal pipe and non-metal pipe. It is harder than plastic pipe, with the high strength of general metal (cold drawn copper pipe strength and the same wall thickness of steel pipe); It is more flexible than ordinary metals, good toughne...Read more -

Milling surface quality of brass strip hot rolling process

The hot rolling process of brass strip is the first process of semi-continuous ingot heating, hot rolling and cold rolling, and it is also the key process of strip surface quality control. In the heating stage, the atmosphere in the furnace, the temperature, the heating time and the quality of co...Read more -

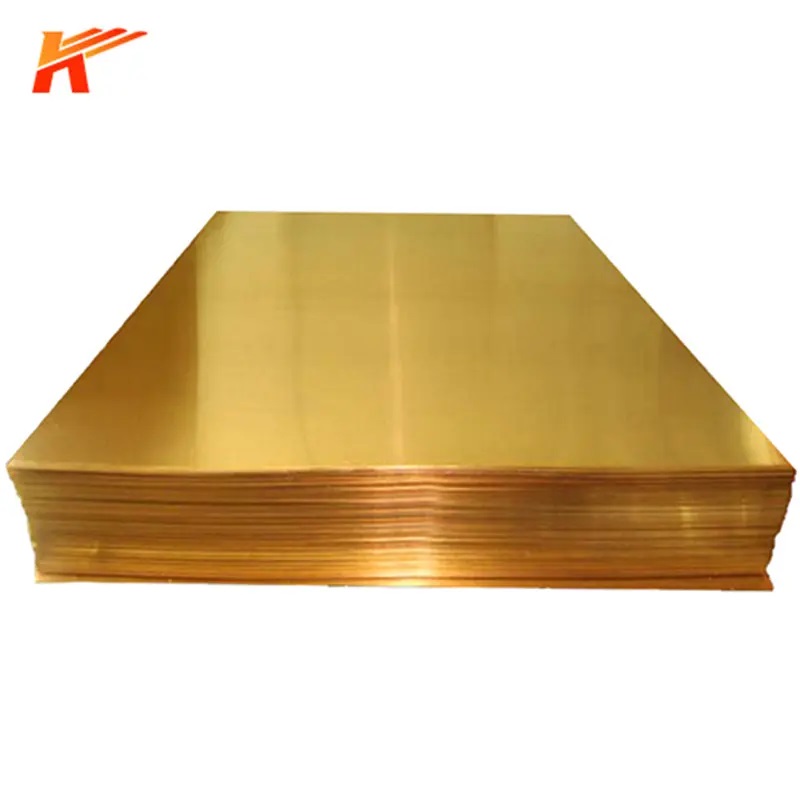

Application and chemical polishing treatment of brass sheet

Brass can be processed into brass sheet, brass wire, etc., is applied to every corner of life. First, it can be used in the HNA industry. Because brass plate whether in cold or hot state, have very good processing performance. So it is widely used in the parts processing of some Marine equipment ...Read more -

Difficulties in welding copper strips

Copper strip has good electrical and thermal conductivity, but there are still many difficult problems in the welding process. The thermal conductivity of red copper belt is much greater than that of steel. Welding heat is more likely to be lost, more likely to cause excessive internal stress, re...Read more -

Processing technology and application of brass strip

Information technology is the precursor of high technology. The main trend of computer development is fast and stable data transmission, bandwidth and low power consumption. In the computer needs a large number of brass strip alloy for spring, contactor, switch and other elastic parts. A large nu...Read more -

Reverse extrusion technology and selection principle of brass sheet

With the development of economy and science and technology, the quality requirements of extruded products are higher and higher, and some special requirements are put forward in some aspects, which promote the rapid development of brass sheet reverse extrusion technology. A new type of reverse ex...Read more -

Brass strip application and processing

Brass strip is a long conductor of rectangular or chamfered sections made of copper, used to carry current in circuits and connect electrical equipment. Because copper is better than aluminum in conducting electricity, brass strip has been widely used in electrical equipment, especially in power ...Read more -

Brass sheet grinding process

Brass sheet polishing refers to the selection of a reflection of the effect, so that the surface of brass sheet is not smooth level shrink, make it more and more bright, leveling the surface of the solution. The key to polishing brass is to adopt two methods: mechanical chemical method and physic...Read more -

Technology of silicon bronze

The casting process of silicon bronze: melting and pouring. Silicon bronze is smelted in an acid induction furnace. The charge should be preheated to 150~200℃ before being put into the furnace, and the electrolytic copper should be cleaned up, roasted at high temperature and thoroughly deoiled be...Read more -

Preparation method and application of high purity copper

High purity copper refers to the purity of copper reaches 99.999% or higher 99.9999%, and its various physical properties are greatly improved than those with low purity. Copper has good electrical and thermal conductivity, and it is malleable and malleable. Copper is commonly used to make wires ...Read more